Steel Industry’s Brake Systems Power Requirements and Heat

Transitioning into the intricacies of the steel industry, it becomes evident that the choice of brake systems revolves around the power available onsite. Electric type brakes, for instance, excel in high-temperature environments, outperforming their hydraulic and pneumatic counterparts. Moreover, older steel mills frequently utilize dirty DC (Direct Current) power. This setup seamlessly integrates with Johnson Magnetic Disc and Drum Brake systems. Our electric braking control systems come with an amazing filter circuit which ensures smooth operation even when dirty DC power it present.

Shifting our focus, we also encounter AC (Alternating Current) thruster drum brakes in the mix. These brakes, with their superior control capabilities, often outshine DC magnet brakes, especially in applications demanding modulated Brake Torque. On the other hand, when it comes to both static and dynamic holding, Johnson DC magnet brakes rise to the occasion. Their adjustable brake torque ensures they remain a popular choice for diverse steel industry needs.

SMLB 19” Thruster drum brake. A/C operated.

Transitioning to the Magnetic Power of DC Brakes

Shifting gears, we delve into the DC Magnet Disc Brakes. These aren’t your typical brakes. Utilizing the power of magnetism, they offer a unique kind of stopping power, ideal for situations that demand rapid and efficient braking. Furthermore, the integration of DC brakes often means reduced wear and tear on machinery, translating to longer lifespans and decreased maintenance costs. In essence, they bring a blend of modern technology and old-school reliability to the table.

The Evolution of Control: Ladle Crane VFD-Controlled Foot Pedal Brakes

And then, evolving further, we encounter the Ladle Crane VFD-controlled foot pedal brakes. Tailored for operators who crave the ultimate control, these brakes redefine precision. By allowing operators to manage braking intensity via foot pedals, they cater to the most minute adjustments. So, whether it’s a slight deceleration or an immediate halt, these brakes respond with unmatched accuracy.

Steel mill scrapyard crane. Service brake.CU 4 DC magnet disc brake with automatic wear adjust.

Applications:

- Gantry Cranes

- Submarine Ladle cars

- Forming Drums

- Hot Strip Mill

- Coil Rollers

- Cold Rollers

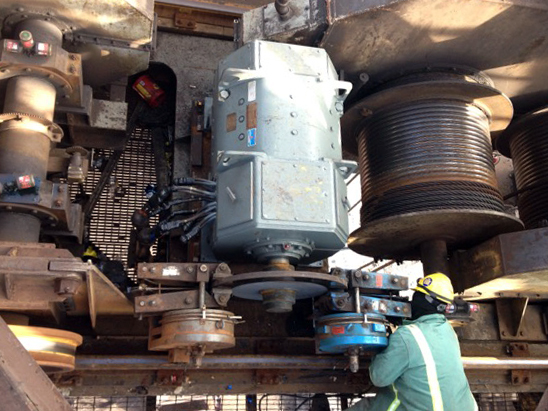

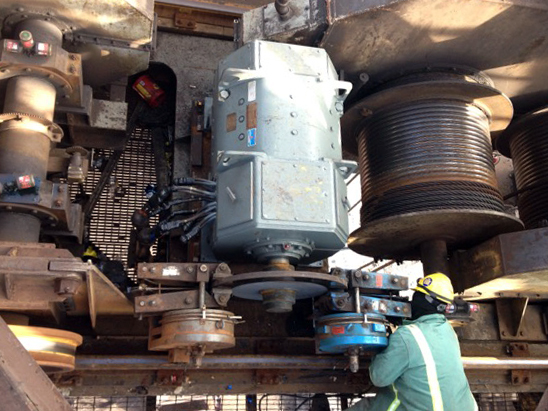

435-ton main hoist and 105-ton auxiliary hoist fitted with SDLX Thruster Drum Brakes with Eldro thruster, self-adjusting feature, and modulated electronic foot pedal control system. This system is used to transport molten steel in a ladle, soft gradual stopping is provided by Johnson Brakes.

435-ton main hoist and 105-ton auxiliary hoist fitted with SDLX Thruster Drum Brakes with Eldro thruster, self-adjusting feature, and modulated electronic foot pedal control system. This system is used to transport molten steel in a ladle, soft gradual stopping is provided by Johnson Brakes.

For more information, fill in our online Forms below:

435-ton main hoist and 105-ton auxiliary hoist fitted with SDLX Thruster Drum Brakes with Eldro thruster, self-adjusting feature, and modulated electronic foot pedal control system. This system is used to transport molten steel in a ladle, soft gradual stopping is provided by Johnson Brakes.

435-ton main hoist and 105-ton auxiliary hoist fitted with SDLX Thruster Drum Brakes with Eldro thruster, self-adjusting feature, and modulated electronic foot pedal control system. This system is used to transport molten steel in a ladle, soft gradual stopping is provided by Johnson Brakes.