High speed container crane fitted with Johnson Storm Brakes (Rail Clamps) and rail brakes, Thruster Drum Brakes and emergency caliper Disc Brakes acting directly on hoist flange.

Four of Model 68HHH dual actuator, spring applied / hydraulically released calliper disc brakes mounted to 84.0″ Diameter Brake Discs on a 4600HP Drawworks System. This model has an impressive 95,000 lbs [422kN] of clamping force per brake.

The mining sector braking requirements are vast. This sector utilizes Conveyor Systems, Grinding Mills, Stackers / Reclaimers, Mine Hoists, and various other types of rotating drive equipment, which require Brake Systems. The brake systems can be extremely large at up to 1 Million pounds [4448 kN] of clamping force, and there are also modest sized brakes, which start at 2900 pounds [12.8 kN] of clamping force. The braking systems can range from simple on/off emergency braking units to the more complex PLC controlled systems, which have several modes of braking response due to the feedback of changing conditions.

Grinding Mills

Johnson TL Series Caliper Disc Brakes

DS Series Caliper Disc Brakes

Mine Hoists

Johnson DS Series Caliper Disc Brakes and Hydraulic PLC Control Systems

Grinders

Johnson TL Series Caliper Disc Brakes

Conveyer Systems

Johnson DS Series Caliper Disc Brakes

In the wood handling crane sector, high duty cycle industrial brakes are required. The high duty cycle is required due to the quick agile crane operations for loading and systematically processing logs. In high duty cycle applications, achieving quick brake response times and multiple stops in succession are important.

Log handling crane fitted with 58HHH toggle lever high duty cycle caliper disc brakes Hydraulic Caliper Disc Brakes and an HU022SR hydraulic Power Unit. The log-handling crane requires less land (work envelope), and is more environmentally friendly when compared to identical raw log handling methods.

In the material handling industry, Stackers, Reclaimers, and Combination Stacker Reclaimers are utilized to move or re-position bulk materials such as coal and iron ore, in an efficient manner. The equipment is typically rail mounted providing movement in one direction and also has a boom, which can be raised or lowered for more accurate bulk material positioning. The typical Stacker is loaded via a dump truck or tractor and has a conveyor belt which moves material to another location. As the Stacker moves along the rails, it creates a systematic pile of Bulk Material for further processing. The dichotomy to the Stacker is the Reclaimer which has buckets that can scoop up the material and reposition in a different location via the conveyor belt. The braking options for a Sacker or Reclaimer can include, high speed brakes on the conveyors / bucket system, and Rail Clamps or Wheel Brakes for stopping or holding the system in a static position when high winds arise.

Stacker Reclaimer

Braking system: Johnson Sill Beam Mounted Storm Brakes (Rail Clamps)

Conveying Systems

Johnson Industries Storm & Parking Brakes division

In-plant Conveying systems

Johnson Industries Storm & Parking Brakes division

Railway & Railcar Clamping, Gripping, and Braking Systems

Johnson Industries Wheel Grippers, Storm & Parking Brakes division

This stacker reclaimer services approximately 2.5 million Tonnes of coal, and can move up to 6,500 Tonnes/hour.

Air Ventilation Control Systems – Brake applications

Ventilation Shaft Fan Brakes

Ducon Pollution Control System

The steel industry typically uses brake systems, which can take advantage of existing power on site, and electric type brakes, which tend to work better within high-temperature environments than hydraulic and pneumatic types. Quite often older steel mills will have DC (Direct Current) Power on site, which lends itself to Johnson Magnetic Disc and Drum Brake systems. The other typical types of brakes are AC (Alternating Current) thruster drum brakes, which can be controlled better than DC magnet brakes for applications where the Brake Torque must be modulated. Johnson DC magnet brakes work well for static and dynamic holding as the brake torque is adjustable

Submarine Ladle cars

Johnson DS Series Caliper Disc Brakes

Gantry Cranes

Johnson DS Series Caliper Disc Brakes

Forming Drums

Johnson DS Series Caliper Disc Brakes

Hot Strip Mill

Johnson DS Series Caliper Disc Brakes

Coil Rollers

Johnson DS Series Caliper Disc Brakes

Cold Rollers

Johnson DS Series Caliper Disc Brakes

435-ton main hoist and 105-ton auxiliary hoist fitted with SDLX Thruster Drum Brakes with Eldro thruster, self-adjusting feature, and modulated electronic foot pedal control system. This system is used to transport molten steel in a ladle, soft gradual stopping is provided by Johnson Brakes.

The ski lift / ropeway industry requires unique brake systems as the variables are typically different for each project. The length of the ski hill dictates the length of the Ski Lift and thus the capacity of the equipment. The brake systems require gradual soft stopping to avoid having people fall down or become injured. The recent designs we have provided include the soft stop on Ski Chair Lifts to avoid excess swing in the Chairs.

Drive Systems

Johnson DS Series Caliper Disc Brakes

Our brakes can be utilized for dynamic stopping, emergency stop, or both. Johnson calliper disc brakes can be electric, air, or hydraulic. The stopping time can be adjusted to suit any application where a gentle soft stop is required.

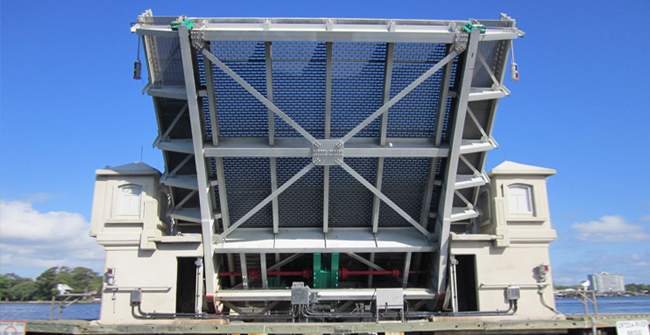

Movable Bridge on Machinery and Motor sides with 2 brakes on each Bridge Leaf Comes with: NEMA 3R Stainless Steel Enclosure, Space Heater (including thermostat), Brake Release Switch, Brake Set Switch, Hand Release, and a Lowering Valve (time delay) in thruster for adjustable brake setting time.

Other Options;

In recent years, the wind industry and hydroelectric systems are being implemented around the world. These systems are typically fitted with high speed and low-speed brake systems. The wind turbines require brakes for maintenance and in the vent of excessively high wind speeds to lock down the equipment.

Turbine Motors

GE Renewable Energy

Applications

Propulsion Shaft Brakes

Rudder Control Brakes

Manoeuvring Brakes

Railway Equipment

Wheel Grippers for Railway Car Dumpers

Escalators

London Underground escalators are fitted with Johnson Elevanja Magnet Disc Brakes.

Google – Energy Kite

Entertainment Industry – Circque du Soleil Rotating Stage, fitted with

Johnson DS Brakes

US Navy – Nuclear Cranes and Submarines, fitted with CX DC Magnet Disc Brakes

Amusement Ride Industry – Disney

Stadium Roofs – Rail Clamps

Aerospace – NASA SMARF, Solid Motor Assembly and Readiness Facility

Reach out to us for the most efficient and affordable braking solutions tailored for you.